Introducing Crosswater Systems

Our Environmental System for Agriculture

Crosswater Systems is the first and only full-service environmental protection system (EPS) capable of dealing with and eliminating large-scale environmental issues. Crosswater Systems can be used for farmland runoff, industrial containment runoff, manure embankments, river banks, parking lots, and any other area in need of reducing runoff contamination.

Patented in the United States, Canadian and European Patented System, it is superior in functionality to any other pervious system. Crosswater Systems provides cost-savings to any contaminate elimination project.

Crosswater Systems is green technology at its best. It is the only 100 percent recycled material and sustainable solution on the market. Once completed, the system is non-hazardous, meets and exceeds MS4 compliance, and provides unparalleled cost benefits. Because the system is self-sustaining, it has an indefinite projected life span.

Crosswater Systems does not compete with other surface systems or containment elimination systems; it simply performs where they do not. Our EPS meets several EPA expectations in one thorough system: pervious, porosity, and remediation for one price and one installation.

Crosswater Systems minimizes the emission of nitrous oxide (N2o). It prevents nitrogen, phosphates, carbon, and other chemicals from entering the environment, and minimizes hydrocarbon gases and pollution from organic waste. Because Crosswater Systems s generated through sustainable and recycled materials, it is LEED compliant and meets all EPA ground water protocols.

At an average cost of $18.00 per square foot, we have produced a green, sustainable system that works versus the enormous cost for systems that have proven ineffective. Other systems require multiple installations and high costs due to major construction efforts. These systems will not meet the expectations of the law nor will they meet multiple standards of performance.

How it Works

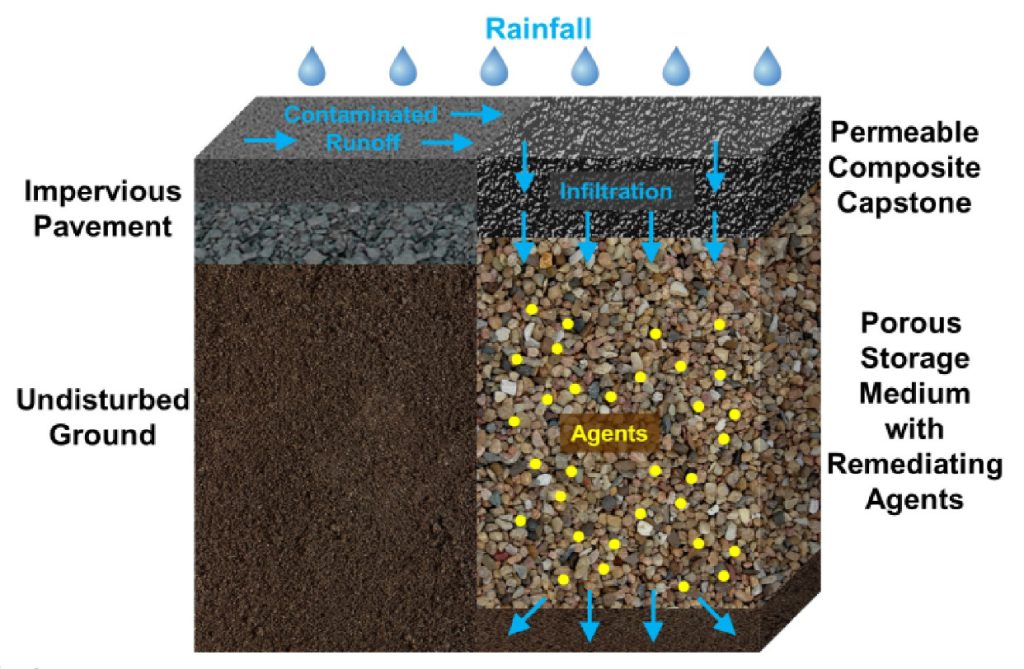

Crosswater Systems is a multi-layered EPS of pervious pavement or water permeable, geotextile material over a layer of storage aggregate used to contain and reduce storm water runoff. Bio-remediation agents are introduced into the storage aggregate to treat, clean and neutralize agricultural contaminants.

The top layer is Capstone, our patented, superior permeable pavement that captures runoff and provides a high rate of entry into the storage aggregate. Made of recycled rubber, recycled concrete, and polymers, Capstone controls surface water runoff, eliminates piping and retention basins, and supports substantial runoff loads.

Capstone costs as much as 50 percent less than the permeable top layer of other systems.

Below the Capstone is our lightweight inorganic aggregate which promotes drainage, aeration, and water retention. Made of shale, slate, or clay, the highly-porous stones have an absorption rate at nearly 25 percent moisture by mass of dry aggregate. Ordinary aggregates retain less than two percent of moisture.

Our aggregates increase ground stability while reducing settlement and erosion. They drain ground and surface water while providing water filtration and purification. These aggregates support our bio-remediation agents and can be used as geotechnical fill, horticulture and landscaping, and to control water runoff and erosion.

The lightweight aggregates are environmentally friendly with a PH of nearly 7. They are strong and durable, do not decompose, and provide consistent, controlled gradations that are resistant to freezing and thawing cycles.

Crosswater Systems injects into the aggregate our EPA-approved microbes, which get to work cleaning or neutralizing animal urine and water-polluting contaminants. They attack the contaminants and convert them into safe water and harmless gases like carbon dioxide. The contamination in the soil or water also stimulates the growth of new microbes, thus providing long-term bio-remediation of the site.

Cost / Benefit Analysis

Using Crosswater Systems EPS creates savings of up to ten times that of any alternative approach over the years due to zero to minimal maintenance requirements. Once installed, the Crosswater Systems EPS has little to no cost for repair, replenishment, upkeep, and/or replacement. The top surface of the Crosswater Systems EPS does not need to be replaced every few years as in other comparative processes. The EPS does not use cost prohibitive underground storage tanks and other ill-advised alternative sewer systems for contaminant elimination.